RTB – Ready To Burn

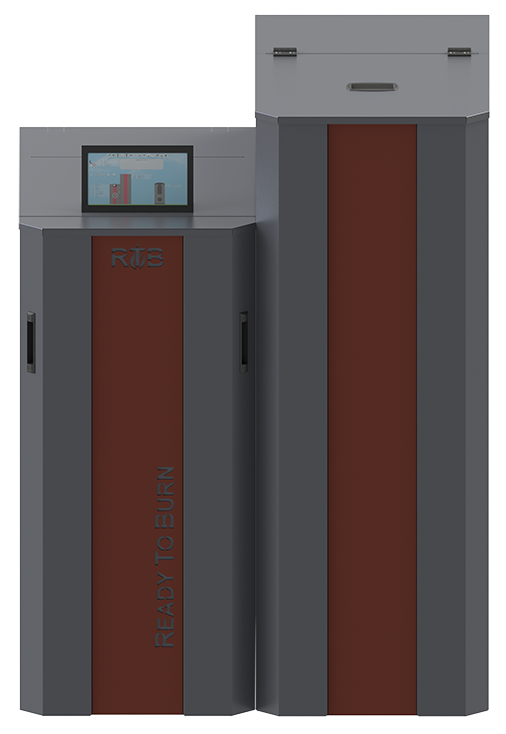

RTB – READY TO BURN. Pellet boiler is an innovation award winning renewable energy product that boasts low emissions and high efficiency! The RTB is proudly designed and produced in Denmark in a fully modernized production facility utilizing the latest in automatized production. This cost effective production platform combined with our focus on the customer experience and comfort allows us to offer the most advanced features in central pellet heating on the market but at a price level that is affordable to all!

The RTBs as standard comes loaded with:

- FREE 3 year subscription to Stokercloud, our online monitoring and operations system,

- 10″ Wireless touch screen running V13 app (available Fall, 2016)

- Possibility to add multiple Android devices

- Automatic cleaning system of the burner and boiler with air compressor

- Self-compressing ash can

- Automatic de-ashing,

- O2 control (available for Fall, 2016 RTB models) and our

- Legendary ‘step-less’ 10-100% modulating burner

Combined, this allows for precise and cost effective heating that is nearly effortless for home or business owners to begin heating with wood pellets. In addition, the systems are designed to be plug-and- play ready which reduces installation cost and can be installed in a modular fashion to add greater functionality and comfort. This includes options for bulk pellet storage, automatic conveyance of the wood pellet to the hopper, ability to cascade up to 8 boilers (up to 640 kW) for commercial applications, and service options for annual service check-ups, online monitoring, and/or technical and commercial management from an authorized RTB dealer. (See your dealer for details)

Standard Features

(select highlighted areas)

Customize your own RTB

Choose kW Size

RTB 10

Range: 2-11 kW

Efficiency: 93,9% (Class 5)

Heats: 150-200 m²*

Replaces: 3500 liters of oil/y

Width: 509 mm

Depth: 846 mm

Height: 1092 mm

*Based on well insulated home

See our manuals here: RTB V13 Manual

RTB 16

Range: 2-17 kW

Efficiency: 91,1% (Class 5)

Heats: 200-300 m²*

Replaces: 5000 liters of oil/y

Width: 509 mm

Depth: 846 mm

Height: 1092 mm

*Based on well insulated home

See our manuals here: RTB V13 Manual

RTB 30

Range: 3-28 kW

Efficiency: 91,4% (Class 5)

Heats: 300-500 m²*

Replaces: 7500 liters of oil/y

Width: 655 mm

Depth: 846 mm

Height: 1092 mm

*Based on well insulated home

See our manuals here: RTB V13 Manual

RTB 50

Range: 5-47 kW

Efficiency: 93,6% (Class 5)

Heats: 500-750 m²*

Replaces: 10000 liters of oil/y

Width: 805 mm

Depth: 1096 mm

Height: 1322 mm

*Based on well insulated home

See our manuals here: RTB V13 Manual

RTB 80

Range: 8-78 kW

Efficiency: 93,6% (Class 5)

Heats: 800-1300 m²*

Replaces: 16500 liters of oil/yr

Width: 962 mm

Depth: 1296 mm

Height: 1518 mm

*Based on well insulated home

See our manuals here: RTB V13 Manual

Choose Hopper

RTB Hoppers

120

Refill every: 3-5 days

Width (mm): 300

Depth (mm): 845

Height (mm): 1300

Only for RTB 10, RTB 16, & RTB 30

Includes inbuilt hopper auger

220

Refill every: 3-5 days

Width (mm): 500

Depth (mm): 845

Height (mm): 1300

Only for RTB 10, RTB 16, & RTB 30

Includes inbuilt hopper auger

320

Refill every: 3-5 days

Width (mm): 700

Depth (mm): 845

Height (mm): 1300

Only for RTB 10, RTB 16, & RTB 30

Includes inbuilt hopper auger

Choose Feed Type

Manual

Got the muscles and don’t mind the work?Then loading your hopper by hand may be right for you. Remember the little extra effort could be well worth it as you see the savings come in. Also, if you decide that you are tired of manually filling your hopper we have plenty of automatic solutions that you can add-on at any time.

See our manuals here: RTB Manual

Cloth Silo w/ Auger Transport

Do you have plenty of space in your boiler room? If so, our Cloth Silo option with 3 meter auger transport is the easiest and most cost effective way to achieve automatic bulk feeding to your system. The Cloth Silo assembles in 15 minutes and comes ‘pellet truck ready‘ with inlets for pumping in pellets by your pellet delivery provider. At the bottom of the silo, pellets are transported via a 3 meter long auger to either a hopper or directly into the burner.

Cloth Silo Dimensions (m) : 2.5 x 2.5 x 1.8-2.3

Capacity : At 3,3 tons the height is 180 cm. At 4,8 ton the height is 230 cm

See our manuals here: RTB Manual

Cloth Silo w/ Vacuum Transport

Do you need to transport pellets some distance to your boiler? If so, then consider the Cloth Silo with Vacuum Transport. The vacuum transport system allows for either a 15 or 20 meter vacuum distance-depending on the vacuum motor size. The Cloth Silo assembles in 15 minutes and comes ‘pellet truck ready‘ with inlets for pumping in pellets by your pellet delivery provider. At the bottom of the silo, pellets are extracted via a vac auger and then vacuum transported to your boiler’s hopper.

Cloth Silo Dimensions (m) : 2.5 x 2.5 x 1.8-2.3

Capacity : At 3,3 tons the height is 180 cm. At 4,8 ton the height is 230 cm

See our manuals here: RTB Manual

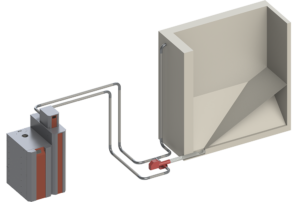

Vacuum Transport w/ self made pellet storage.

Prefer to build your own pellet storage? Then consider adding the vacuum transport system to your self made pellet storage. The vacuum transport system includes a vacuum auger to extract the pellets from your storage unit and vacuum’s the pellets to your boiler’s hopper. Please note that during construction of your pellet storage the side walls must be angled as to allow for the pellets to easily fall to the extraction area. (Contact your RTB dealer for advise)

See our manuals here: RTB Manual

Choose Accessories

Hot Water Priority Kit

Never be stuck without hot water! With the hot water priority kit your system will be able to monitor the temperature of your hot water tank and prioritize the distribution of hot water when the tank temperature gets below a certain specified threshold. This feature will also work during the summer time when heating demands are low.

See our Installation guides.

Extension Module

Need more outputs? The new RTB with V13 wireless screen is delivered as standard with extra outputs to connect to accessories, for instance hot water priority and a weather compensation zone valve. However, if you find that you would like to add more accessories to your system the extension module with 7 extra outputs is an ideal choice to get the extra functionality.

See our manuals here: RTB Manual

Weather Compensation Kit

Get stable indoor temperatures regardless of the weather! With the weather compensation kit you are able to operate your pellet boiler in a more energy efficient manner with less cycling; while ensuring that indoor temperatures are never too hot, nor too cold.

How it works: The system works with a weather compensation blending valve that monitors the forwarding temperature to the heating zone. When outdoor temperatures get colder, the valve regulates itself to provide a higher forwarding temperature to compensate for the zone’s increased consumption. When outdoor temperatures increase the blending valve reduces the forwarding temperature to the zone. The result is even and stable indoor temperatures!

See our manuals here: RTB Manual

Draft Regulator

Having a clean burning pellet boiler depends greatly on balancing the air to wood pellet fuel mixture during the combustion process. If it is particularly windy outside the chimney could be producing an overdraft that could disrupt the fuel to air mixture in the combustion; essentially causing to much air to be pulled into the burner. The draft regulator is an essential component in the installation of a biomass system to prevent overdraft in the chimney from influencing the combustion. As such, you must always ensure that your chimney always includes a draft stabilizer.

See our manuals here: RTB Manual